sample

product features

product description

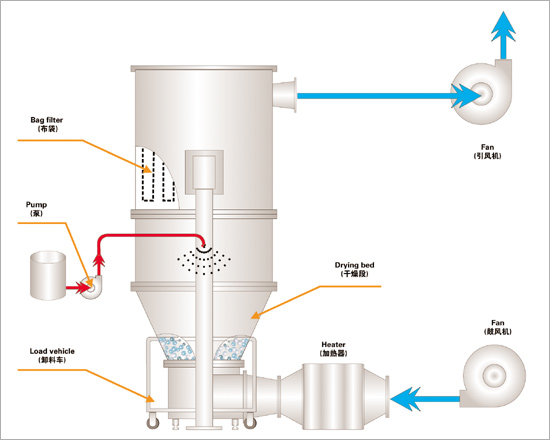

Fluidized bed granulator is one of the equipments commonly used in the production process of solid preparations in the pharmaceutical industry,suitable for pharmaceutical、food、chemical and other industries. It fully complies with GMP pharmaceutical requirements for multiple processes (mixing, granulation and drying) in a closed container at one time in the granulation process, which reduces cumbersome processes, saves time, and can effectively control the flying of material powder, protect the production environment and prevent cross-contamination at the same time.It has the advantages of uniform size, round shape, good fluidity and good compressibility compared to granules made by other processes.

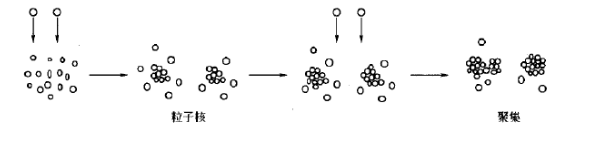

The formation of particles is that when the binder is sprayed on the suspended and loose materials, the binder droplets wet the powder in contact and coalesce around themselves to form particle nuclei, and at the same time, the droplets that continue to spray fall on the particles. Bonding and bridging are generated on the surface of the particle core, so that the particle core and the particle core are cross-linked and bonded to each other, and gradually agglomerate and grow into larger particles.

In the fluidized bed drying process, the temperature usually changes in three stages: in the first stage of drying, the material temperature is gradually heated from room temperature to the wet bulb temperature of hot air;in the second stage, the material keeps the wet bulb temperature of the hot air unchanged until the moisture content of the material drops to the critical humidity, at which time the material no longer contains free moisture; then, in the third stage of temperature rise, the material loses bound water.When drying, the inlet air temperature should not be too high, the solvent on the surface of the particles evaporates too quickly, and the inner layer of the solvent is blocked from diffusing outward, resulting in a large number of particles with dry outer temperature and inner temperature. If the temperature is too low and the drying time is too long, a lot of fine powder will be produced.

2.Dual-chamber filtration system ensures continuous fluidization even during oscillating cleaning dust.

3.The air inlet cleans the air through a three-effect filter, and then heats the air to the set temperature through electric heating or steam heating.

4.Inlet box with side door for easy filter replacement.

5.The drain outlet can be rotated 360, which is convenient to match the floor drain in any location of the customer's workshop.

6.The structure of the cylinder is calculated by accurate aerodynamics, and the uniform airflow drives the material to circulate evenly in the cylinder.

7.Excellent speed regulation performance, set pressure relief hole, safe to use

Technical parameters

Model |

DPL-ⅡA | DPL3/5 |

|

Material Container |

Top Spray (L) | 9 | 18.5 |

| Bottom-Spray(L) | 5 | 10 |

|

| Side Spray (L) | 7.5 | 9 |

|

Capacity |

Top Spray(Kg/batch) | 0.5-3 | 1.5-5 |

| Bottom-Spray(Kg/batch) | 0.25-2 | 0.5-3 |

|

| Side Spray (Kg/batch) | 0.5-2 | 1-2.5 |

|

Compressed Air |

Pressure Mpa | 0.4-0.6 | 0.4-0.6 |

| Onsumption M³/min | 0.4 | 0.5 |

|

Blower Power Kw |

4 | 5.5 |

|

Heating Power Kw |

4.5 | 12 |

|

Overall Dimensions |

L(mm) | 1800 | 2250 |

| W(mm) | 860 | 1050 |

|

| H(mm) | 2385 | 2850 |

|

| diameter(mm) | 300 | 400 |

|

Associate machine

- Address

- Block 1, Machinery area, Yunjiang industrial zoon, Feiyun, Ruian, Zhejiang, China.

- Cellphone:

- +86-13967712128

- office@aligned-machinery.com