01

01

Product detail

sample

product features

product features

01

product description

The machine fully complies with GMP pharmaceutical requirements, featuring low consumption、no pollution, security. It can complete the process of mixing, humidifying, granulating and other at one time,suitable for pharmaceutical、food、chemical and other industries. And it’s 4-5 times higher than the traditional process, which is reflected in about 2 minutes of dry mixing and 1-4 minutes of granulation for each batch. It is mainly composed of conical hopper, impeller, chopper, feeding device, liquid feeding device, discharging and control system, and auxiliary systems such as air sealing, water cleaning, and jacket water cooling. In the container, the material and the binder are fully mixed by the impeller to form a moist soft material, and then cut into uniform wet particles by the high-speed chopper blades.

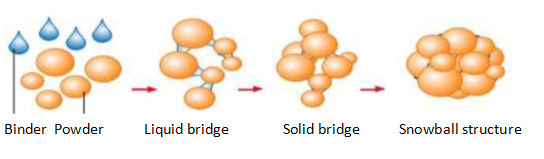

Working Principle

The process consists of two programs including mixing and granulating.

Powder material can be charged into the material pan from the conical hopper and continue to rotate in the container under the action of mixing blade once the hoper is closed. In the meanwhile, all materials grow up the shape of liquid bridge under continuous effects of conical wall. Under the action of extrusion, friction as well as crumb by blade and conical tank wall, all material is gradually turn for loosen. At last while opening the hopper outlet, waterish particles are pushed off under the centrifugal effects blade.

Feature

1. Auto startup of safety pin in fixed position while opening the lid guarantees reliable operation.

2. Belt drive system has advantages of overload protection, simple maintenance, free of oil lubrication and leakage.

3. Oblique designed liner impeller blade applies for the mixture of processed material which drops down at certain height, free of sticking on lid.

4. Container lid is multifunctional design, fitted with observation port, auto/manual dipping port, exhaust port, auto cleaning port, auto spraying port, vacuum loading port.

5. An automatic water circulation system is built under bottom container.

6. Three cycles of seal rings and air seal used for the bearings of impeller and chopper, no dirty or oil backflows to processed container.

7. Air seal system is common for air and water circulation, both for cleaning bearing gaps and pressure setting.

8. Stringent mirror polish technology applied to full container.

9. Outlet Vent filter 0.22 micron allowing evacuation of compressed air used in air purged impeller and chopper seals.

10. Conical sieve mill (Wet Mill) is mounted on discharge port, equipped with milling screen and two rotor arms (square or round) or triangular blades that rotates at a speed up to 3000 RPM (Option).

2. Belt drive system has advantages of overload protection, simple maintenance, free of oil lubrication and leakage.

3. Oblique designed liner impeller blade applies for the mixture of processed material which drops down at certain height, free of sticking on lid.

4. Container lid is multifunctional design, fitted with observation port, auto/manual dipping port, exhaust port, auto cleaning port, auto spraying port, vacuum loading port.

5. An automatic water circulation system is built under bottom container.

6. Three cycles of seal rings and air seal used for the bearings of impeller and chopper, no dirty or oil backflows to processed container.

7. Air seal system is common for air and water circulation, both for cleaning bearing gaps and pressure setting.

8. Stringent mirror polish technology applied to full container.

9. Outlet Vent filter 0.22 micron allowing evacuation of compressed air used in air purged impeller and chopper seals.

10. Conical sieve mill (Wet Mill) is mounted on discharge port, equipped with milling screen and two rotor arms (square or round) or triangular blades that rotates at a speed up to 3000 RPM (Option).

02

Technical parameters

| Model | HLSG-10 | HLSG-30 | HLSG-50 | HLSG-100 | HLSG-200 | HLSG-300 | HLSG-400 | HLSG-600 | HLSG-800 |

| Hopper Capacity | 10L | 30L | 50L | 100L | 200L | 300L | 400L | 600L | 800L |

| Working Capacity | 2-8L | 6-24L | 10-40L | 20-80L | 40-160L | 60-240L | 100L-300L | 150L-440L | 200L-600L |

Feed Qty |

1-4 Kg/batch | 3-12 Kg/batch | 8-20Kg/batch | 15-40 Kg/batch | 30-80Kg/batch | 30-120Kg/batch | 50-150Kg/batch | 75-220Kg/batch | 100-300Kg/batch |

| Operation Time | Mixing about 2 minutes granulating about 7-14 minutes each batch | Mixing about 2 minutes granulating about 7-14 minutes each batch | Mixing about 2 minutes granulating about 7-14 minutes each batch | Mixing about 2 minutes granulating about 7-14 minutes each batch | Mixing about 2 minutes granulating about 7-14 minutes each batch | Mixing about 2 minutes granulating about 7-14 minutes each batch | Mixing about 4 minutes granulating about 10-15 minutes each batch | Mixing about 8 minutes granulating about 15-20 minutes each batch | Mixing about 8 minutes granulating about 15-20 minutes each batch |

| Finished Product Granularity | About Φ0.14-Φ1.5mm (12 mesh-100 mesh) | About Φ0.14-Φ1.5mm (12 mesh-100 mesh) | About Φ0.14-Φ1.5mm (12 mesh-100 mesh) | About Φ0.14-Φ1.5mm (12 mesh-100 mesh) | About Φ0.14-Φ1.5mm (12 mesh-100 mesh) | About Φ0.14-Φ1.5mm (12 mesh-100 mesh) | About Φ0.14-Φ1.5mm (12 mesh-100 mesh) | About Φ0.14-Φ1.5mm (12 mesh-100 mesh) | About Φ0.10-Φ2.5mm |

| Mixing Motor | 2.2KW | 3KW | 5.5KW | 7.5KW | 15KW | 18.5KW | 22KW | 30KW | 37KW |

Mixing Blade Rotating Speed |

50-500 rpm | 25-500 rpm | 25-500 rpm | 30-250 rpm | 30-260 rpm | 30-220 rpm | 20-200 rpm | 20-200 rpm | 20-200 rpm |

| Granulating Motor | 0.75KW | 1.1KW | 1.5KW | 3KW | 4KW | 5.5KW | 7.5KW | 11KW | 11KW |

Granulating Blade Rotating Speed |

50-3000 rpm | 50-3000 rpm | 50-3000 rpm | 50-3000 rpm | 50-3000 rpm | 50-3000 rpm | 50-3000 rpm | 50-3000 rpm | 50-3000 rpm |

Compressed Air |

0.15m³ 0.7mpa | 0.15m³ 0.7mpa | 0.3m³ 0.7mpa | 0.3m³ 0.7mpa | 0.3m³ 0.7mpa | 0.5m³ 0.7mpa | 0.5m³ 0.7mpa | 0.5m³ 0.7mpa | 0.6m³ 0.7mpa |

| Cooling Water Connector | Φ8mm | Φ8mm | Φ8mm | Φ8mm | Φ10mm | Φ10mm | Φ10mm | Φ10mm | Φ12mm |

| Compressed Air Port | Φ8mm | Φ8mm | Φ8mm | Φ8mm | Φ10mm | Φ10mm | Φ10mm | Φ10mm | Φ12mm |

| Machine Size | 1280×530×1320 mm | 1500×550×1350 mm | 1750×600×1620 mm | 1760×600×1660 mm | 2180×810×1950mm | 2420×1060×2150mm | 2420×1060×2150mm | 2980×1200×2500mm | 3180×1500×2800mm |

| Weight | 350kg | 450kg | 600kg | 800kg | 1300kg | 1500kg | 1800kg | 2200kg | 2700kg |

03

Associate machine

- Address

- Block 1, Machinery area, Yunjiang industrial zoon, Feiyun, Ruian, Zhejiang, China.

- Cellphone:

- +86-13967712128

- office@aligned-machinery.com

Copyright © 2020 Aligned Machinery Co.,Ltd.

Web design by LIANKE

Copyright © 2020 Aligned Machinery Co.,Ltd.