sample

product features

product description

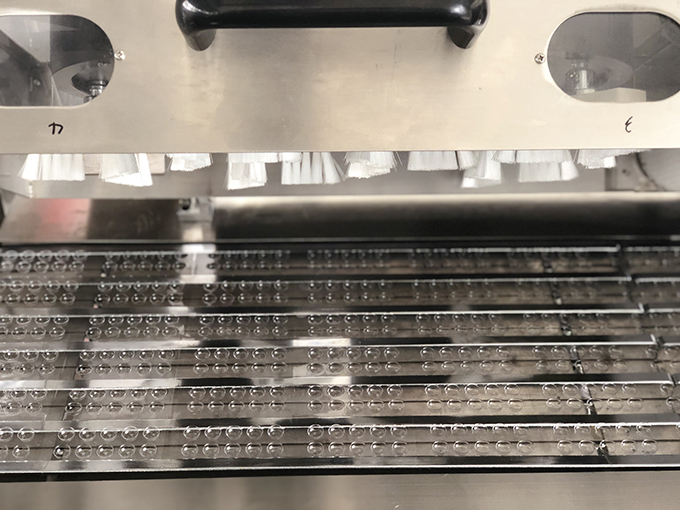

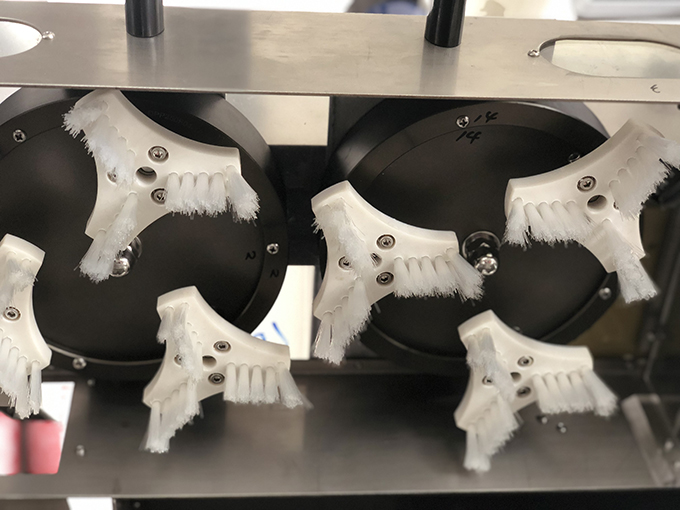

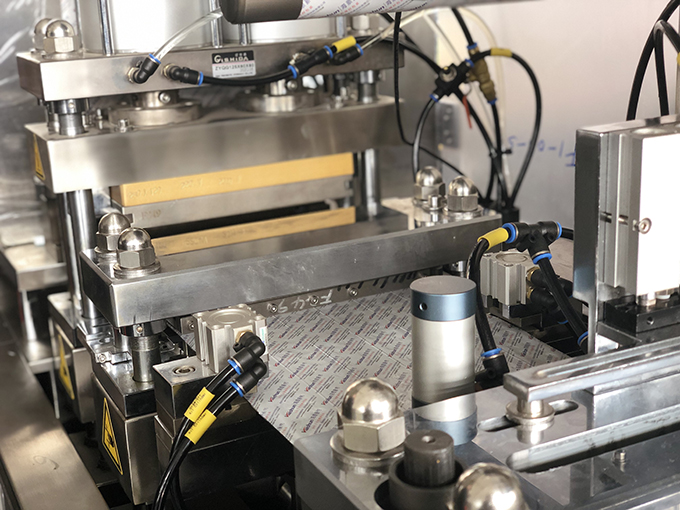

DPP-260 Automatic Blister packing Machine is our advanced equipment designed under updated improvement. Adopts of the integral technology applying frequency inverter for speed control and mechanism, electricity, light, and air to machine. Its design is in strict compliance with GMP standards and takes lead in the blister packer’s field. Featuring advanced functions, simple operation, high output, and the machine is ideal packing equipment for large and medium-sized pharmaceutical enterprises, health food, and foodstuff plant.

Technical parameters

|

Max. Punch Speed |

AL/PL:40-60 times/min(stand type) |

|

|

AL/AL:20-40 times/min |

||

|

Max. Production Capacity |

AL/PL:350 thous. /h |

|

|

AL/AL:150 thous. /h |

||

|

Adjustable Range Of Stroke |

Standard dispose≤120mm(according to the customers′ Requirement) |

|

|

Max. Forming Area |

245x112 mm |

|

|

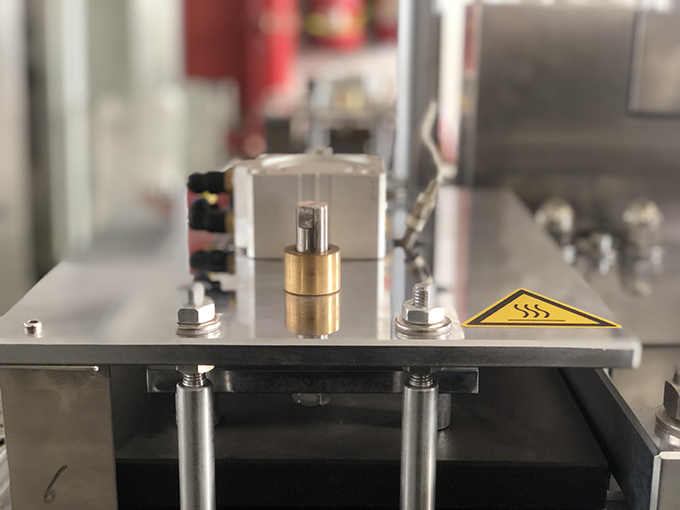

Max. Forming Depth |

AL/PL:14 mm |

|

|

AL/AL:14 mm |

||

|

Specification Of Packaging Material |

Note:The Width Of The Material 130-260mm |

Medicine PVC:260x0.25(0.15-0.5) mm |

|

Heat-sealing PTP:260x0.02 mm |

||

|

Power Connection |

There Phases Four Wires: |

|

|

Total Power |

6.4KW |

|

|

Main Motor Power |

2.2 KW |

|

|

Forming Upper and Lower Heat power |

1.5 KW(x2) |

|

|

Heat-sealing Heat Power |

1.2 KW |

|

|

Air Pump(Air Compressor)Volume |

≥0.38 m3/min |

|

|

Dimensions Of Overall Machine(L×W×H) |

3940x720x1580mm |

|

|

Dimensions Of Packing Case(L×W×H) |

4100x880x1740mm |

|

|

Dimensions Of Separate Packing Cases(L×W×H) |

2000x880x1740mm and 1550x880x1740 |

|

|

Weight |

1800 kg |

|

Associate machine

- Address

- Block 1, Machinery area, Yunjiang industrial zoon, Feiyun, Ruian, Zhejiang, China.

- Cellphone:

- +86-13967712128

- office@aligned-machinery.com