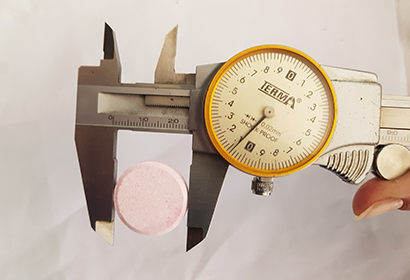

sample

product features

product description

1. ZPW series tablet press machine can be single outlet or double outlet. The double-outlet type can complete a second working cycle per rotation, and produce 46 tablets (a model with a higher output can be selected according to demand), thereby improving the working efficiency of the equipment. At the same time, the double outlet type can press two-color tablets.

2. The whole machine is fully enclosed, and the four sides of the workbench are protected by plexiglass doors, which is convenient for viewing abnormalities and opening inspections

3. The worm, worm gear, and other transmission structures, as well as the motor and lubrication structure are sealed inside the machine under the workbench, separated from the tabletting operation structure to avoid cross-contamination and meet GMP requirements.

4. Both the high-speed rotary part and the force mechanism adopt rolling friction to reduce wear, reduce power consumption, and increase the service life of the machine.

5. ZPW series tablet press machine adopts imported frequency conversion speed regulation and hydraulic system, which is more stable when pressing tablets and prevents the phenomenon of broken punches.

6. When the equipment is overloaded, it can automatically stop, brake, and alarm, and the operation is safe and reliable.

Technical parameters

Die Amount |

45 stations |

41stations |

35stations |

31tations |

27 stations |

23 stations |

Max.Pressure |

100KN |

100KN |

100KN |

100KN |

100KN |

100KN |

Max.Filling Depth |

17 mm |

17 mm |

17 mm |

17 mm |

23 mm |

23 mm |

Max.Pressure Diameter |

11 mm |

12 mm |

13 mm |

20 mm |

25 mm |

27 mm |

Min.Pressure Diameter |

7 mm |

7 mm |

7 mm |

7 mm |

7 mm |

7 mm |

|

RPM |

16-36(r/min) |

16-36(r/min) | 16-36(r/min) | 16-36(r/min) | 16-36(r/min) | 16-36(r/min) |

|

Working Capacity |

100000-180000 (P/h) |

100000-174000(P/h) |

60000-150000(P/h) |

50000-133000(P/h) |

45000-95000 (P/h) |

40000-83000 (P/h) |

|

Power Supply |

4KW 380V 50HZ(220V 60HZ) |

4KW 380V 50HZ(220V 60HZ) |

4KW 380V 50HZ(220V 60HZ) |

4KW 380V 50HZ(220V 60HZ) |

4KW 380V 50HZ(220V 60HZ) |

4KW 380V 50HZ(220V 60HZ) |

|

Overall Dimension |

1300*1400*1850 (mm) |

1300*1200*1750(mm) |

1300*1200*1750(mm) |

1300*1200*1750(mm) |

1300*1200*1750 (mm) |

1300*1200*1750 (mm) |

|

Weight |

2000 (kg) |

2000 (kg) |

2000 (kg) |

2000 (kg) |

2000 (kg) |

2000 (kg) |

Associate machine

- Address

- Block 1, Machinery area, Yunjiang industrial zoon, Feiyun, Ruian, Zhejiang, China.

- Cellphone:

- +86-13967712128

- office@aligned-machinery.com