sample

product features

product description

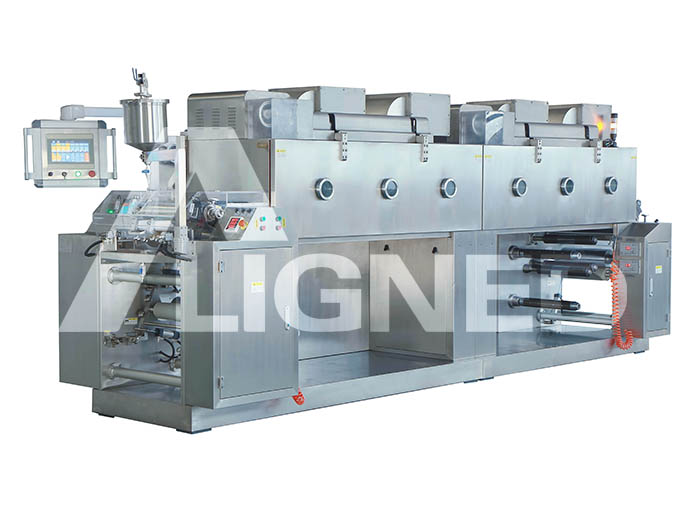

Oral Dissolving Film Making Machine produces thin films from liquid materials.

It is designed to make oral films that dissolve quickly, as well as strips for breath fresheners and other uses.

The machine has broad applications in the pharmaceutical and food industries.

The benefits that you will observe when using the Oral Dissolving Film Making Machine include:

● The machine relies on a modular design with few components, making it simple to operate and maintain.

● It is equipped with automatic working length and speed recording and automatic oven temperature control to ensure efficient and high-quality production.

● All parts in contact with the material are made of stainless steel and food-grade materials, meeting "GMP" requirements.● PLC control panel can easily adjust all data parameters.

● The air intake and exhaust pipes have been redesigned into cylinders to facilitate cleaning and prevent cross-contamination.

● It has a tempered glass viewing window for effortless cleaning and observation,eliminating any blind spots.

There are different types of Oral Dissolving Film Making Machines that you can choose from.

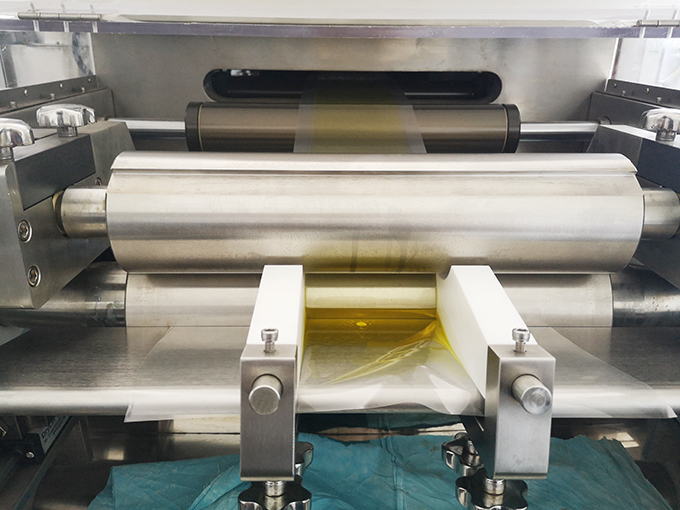

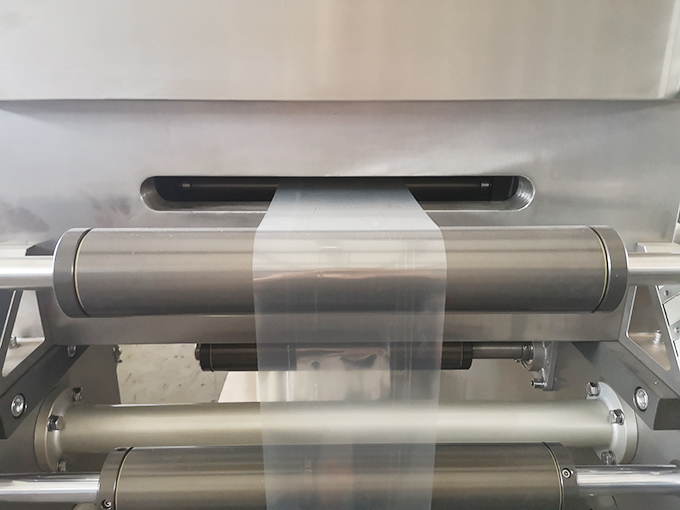

The ODF Making Machine employs various modules to accomplish its task.

The primary labor modules include:

Whenever you purchase or customize an Oral Dissolving Film Making Machine,you need to have specific requirements.

Some of the key factors to consider include:

Determine the required production capacity based on your needs, including hourly or daily output.

Ensure that the production capacity of your Oral Dissolving Film Making Machine meets your needs to ensure productivity and timely delivery.

When selecting an Oral Dissolving Film Making Machine,consider its level of technology and quality control capabilities.

Make sure the machine uses advanced technology and processes with precise drug release control and high quality dissolution film preparation.

Choose suppliers with good reputation and reliability,and ensure that the machine is easy to maintain and repair.

This can minimize stop time and maintenance costs.

Choose a supplier that offers comprehensive service and technical support,including training, installation and after-sales service.

Evaluate the user interface and operation of the machine.

Choose machines that are easy to use and learn to minimize training costs and increase productivity.

It ensures the machine's proper working condition and compliance with cGMP requirements.

Manufacturers must conduct a factory assessment before releasing the machine.

It is provided after the installation and extensive testing of the Oral Dissolving Film Making Machine.

After the installation is completed,the machine is tested to ensure proper functionality before issuing the IQ document.

The OQ document is received after the technician tests the machine post-installation.

It confirms that the machine is working properly before accepting the document from the manufacturer.

Technical parameters

|

Project |

Parameter |

|

Max Production Width |

360mm |

|

Roll Width |

400mm |

|

Speed |

0.1-1.5m/min (Depends on products formula and process) |

|

Unwinding Diameter |

≤Φ350mm |

|

Winding Diameter |

≤Φ350mm |

|

Method Of Heat & Dry |

Heating by external stainless-steel heater, hot air circulation in centrifugal fan |

|

Temperature Control |

30-80°C±2°C |

|

Edge Of Reeling |

±3.0mm |

|

Power Supply |

16Kw |

|

Overall Dimension |

2980*1540*1900mm |

Associate machine

- Address

- Block 1, Machinery area, Yunjiang industrial zoon, Feiyun, Ruian, Zhejiang, China.

- Cellphone:

- +86-13967712128

- office@aligned-machinery.com