sample

product features

product description

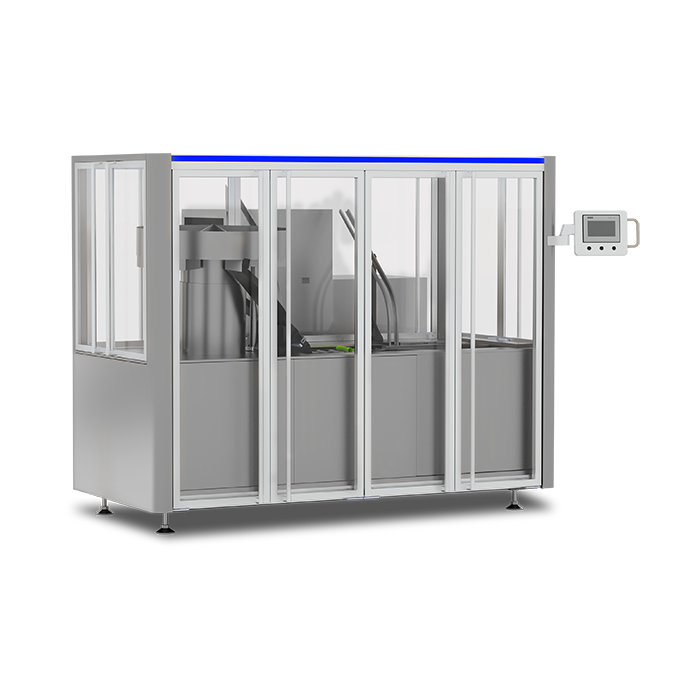

1.What is Automatic Effervescent Tablet Tube Filling Machine?

Setting the parameters on the automatic tube bottling machine to quickly load standardized quantities of tablets into tubes to complete batch production.

Your effervescent tablet production is not complete without an automatic effervescent tablet tube filling machine.

Using the effervescent tablet filling machine can realize automation of procedures. It reduces material waste in operations, improves product accuracy, maintains product consistency, and increases production capacity.

Effervescent tablets are sensitive and quickly react to the environment. Automatic effervescent tablet tube filling machine can protect these tablets, ensuring they remain in perfect condition before using them.

Installation of humidity detection devices to ensure that the production environment is up to standard, helping to keep the effervescent tablets in perfect condition.

It can realize automatic sorting, automatic cap feeding, automatic counting, automatic capping and automatic bottle output, etc., and adopts intelligent control of counting and filling system, pressing caps at a speed of up to 120 bottles per minute, and completing the effervescent tablets tube loading quickly and efficiently.

The cap vibrating unit automatically loads the caps to the capping station by restructuring and aligning the cap to rack.

When the tablets appear on the tablet feeder through the machine hopper, it will automatically send the tablets to the filling position.

Automatic unscrambling the bottles and send them to the bottling mechanism.

The bottling mechanism automatically counts the tablets and arranges them on each track.

It pushes the cylinder which delivers the tablets into the bottle once they are ready.

● CE Quality Specifications (for health quality compliance)

● Current Good Manufacturing Practices (GMP) Quality Specifications

● Food and Drug Administration (FDA) Quality Specifications

Effervescent tablet packing machine occupies only 5m² in your plant, saving resources for other areas where space is needed.

The design of pull-out molds can be changed to different sizes within two minutes.

We are the only one in China that can produce 120 tube/min.

On the one hand, multiple testing devices at each stage to ensure overall automation and efficient operation, on the other hand,the filling machine will only work if the humidity is detected to be up to standard.

Noise not more than 75 dB at a distance of 1 meter from machine.

The vibrator will only start working again if the detection device detects that the number of products is not up to standard, greatly reduces machine wear and tear.

Matching Vacuum Cleaner can avoid material dust and dust buildup from machine operation.

When it's time to clean your equipment, all you need is an absorbent towel with a sanitizer and you've got a brand new piece of machine.

1 year. Within one year, if the spare parts are damaged, we can send new spare parts for free, but you need to pay the logistic fee.

With a number of passport-holding technicians at your service, we provide comprehensive after-sales service and technical support to ensure that you can get the solution in time.

Among the specifications that you can ask for customization include the packaging size, speed, and more.

10. What industries can Automatic Effervescent Tablet Packing Machine be applied to?

The industry requires the filling machine to assist in packaging effervescent tablets for medical purposes.

The industry uses specialized types of filling machines in putting food and beverages into different sizes of tubes.

It ensures that the food and beverage is filled in accordance to the filling requirements and specifications.

It assists in filling dietary supplements as well as food additives in different nutraceutical companies.

Some companies prefer packaging the substances in tubes thus the need of the tube filling machine.

Technical parameters

|

Max. Output |

120tube/min |

|

Max. Tablet Feeding Speed |

98000pc/h |

|

Tablet Diameter |

16-33mm |

|

Tablet Thickness |

3-12mm |

|

Tablet Hardness |

≥40N |

|

Bottling Quantity |

5-20pc |

|

Tube Length |

60-200mm |

|

Tube Diameter |

18-35mm |

|

Power Supply |

380V 50HZ 3P |

|

Power |

4.5KW |

|

Overall Size |

2452mm*1206mm*1991mm |

|

Weight |

About 715KG |

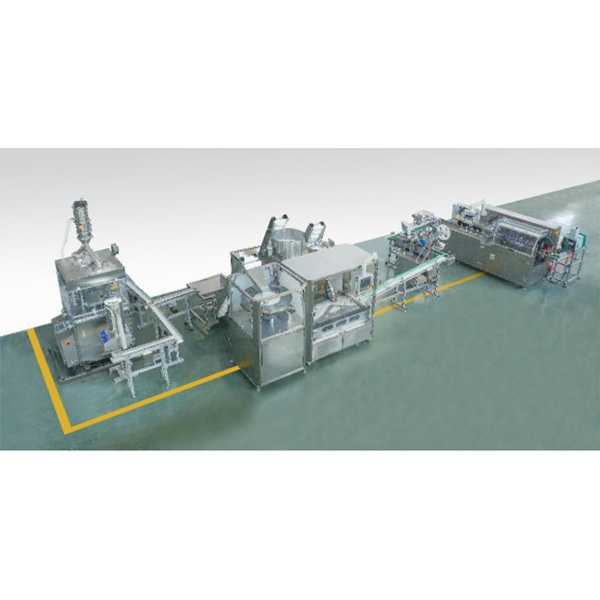

Associate machine

- Address

- Block 1, Machinery area, Yunjiang industrial zoon, Feiyun, Ruian, Zhejiang, China.

- Cellphone:

- +86-13967712128

- office@aligned-machinery.com